Blitzrobotik

China is automating its industries at world-historic scale and speed, America must respond in kind

Everybody knows that China has become "the world’s factory", but many people retain the notion that the American manufacturing base is both more sophisticated and capable of scaling to meet the demands of crisis scenarios than China's. This is no longer true, have been untrue for quite some time, and is getting even less true at an alarming rate, all while people hang onto priors that are at least several decades out of date.

In the last several years PRC has deployed industrial automation at astonishing speed and scale. Western - particularly American - policymakers are asleep at the wheel and have orchestrated no credible response whatsoever. If we don't turn this around we are looking at an industrial performance gap that will lead to our few remaining lucrative advanced industries relocating to China because it will be the only place in the world where they can operate at the leading edge.

The military implications of this gap are even more alarming. America's "Arsenal of Democracy" depended on titanic civilian industrial works that outclassed every other country in the world at the time. This was accomplished in the wake of the First World War, in which much of Europe's industrial capacity was reduced to rubble. This was extended by the Second World War which reduced Europe's remaining industrial assets to rubble. China's manufacturing capacity advantage today is similar to America's after the First World War in all but one respect: they built it up in peacetime, with the help of American and European finance. If we allow that gap to widen, we set ourselves up as losers-by-default in a Third World War that seems to draw nearer every day.

We can close this gap, and perhaps even shoot past China, but it will require a whole-of-government effort. I hope that policymakers are up to the challenge, because the default outcome is geopolitical weakness and economic obsolecense.

Overview

Chinesische Blitzrobotik1 … 5x the robots in 2023 compared to 2017 is a world-historic pace of deployment, America isn't even trying to keep up

What is to be done? … cut off capital and technology flows to PRC, subsidize domestic industrial automation, favor startups over capital-inefficient legacy firms, fix tax law

Das kapital (properly understood) … we think of capital in a very weird and ahistoric way, finance is best considered as an abstraction atop capital

Chinesische Blitzrobotik

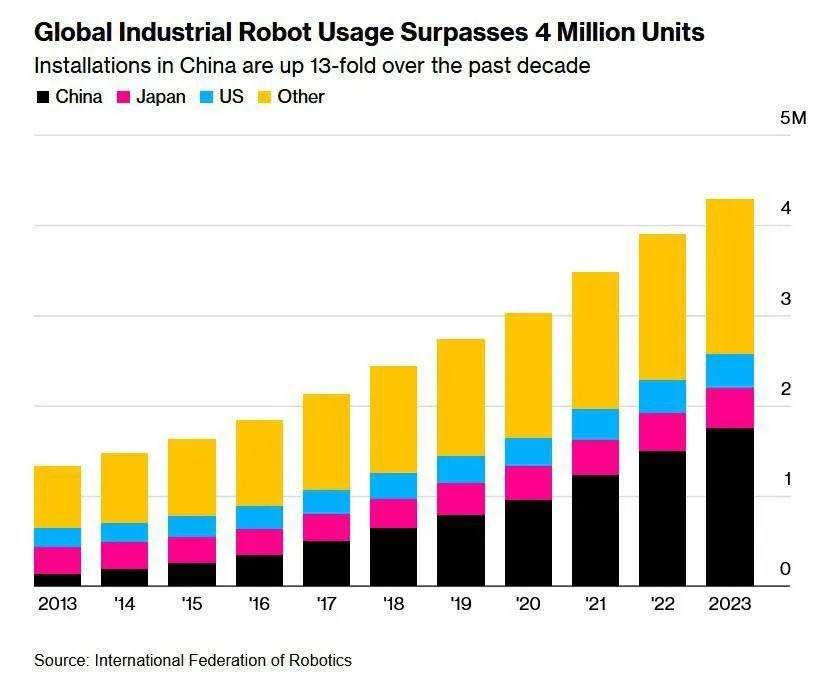

A few months ago I came across a distressing dataset from the International Federation of Robotics. This plot in particular stood out to me:

PRC adds roughly as many industrial robots per year as the US has total. If PRC continued on the above trend they probably cracked 2 million robots sometime earlier this year. By the end of 2025 they could easily have half of all industrial robots globally.

In absolute terms, China added more industrial robots in 2023 than the rest of the world combined. This is a world-historic effort to automate industry from top to bottom. PRC leadership was completely serious about their "Made in China 2025" targets, and American leadership did not take them seriously. These are the results of our complacency.

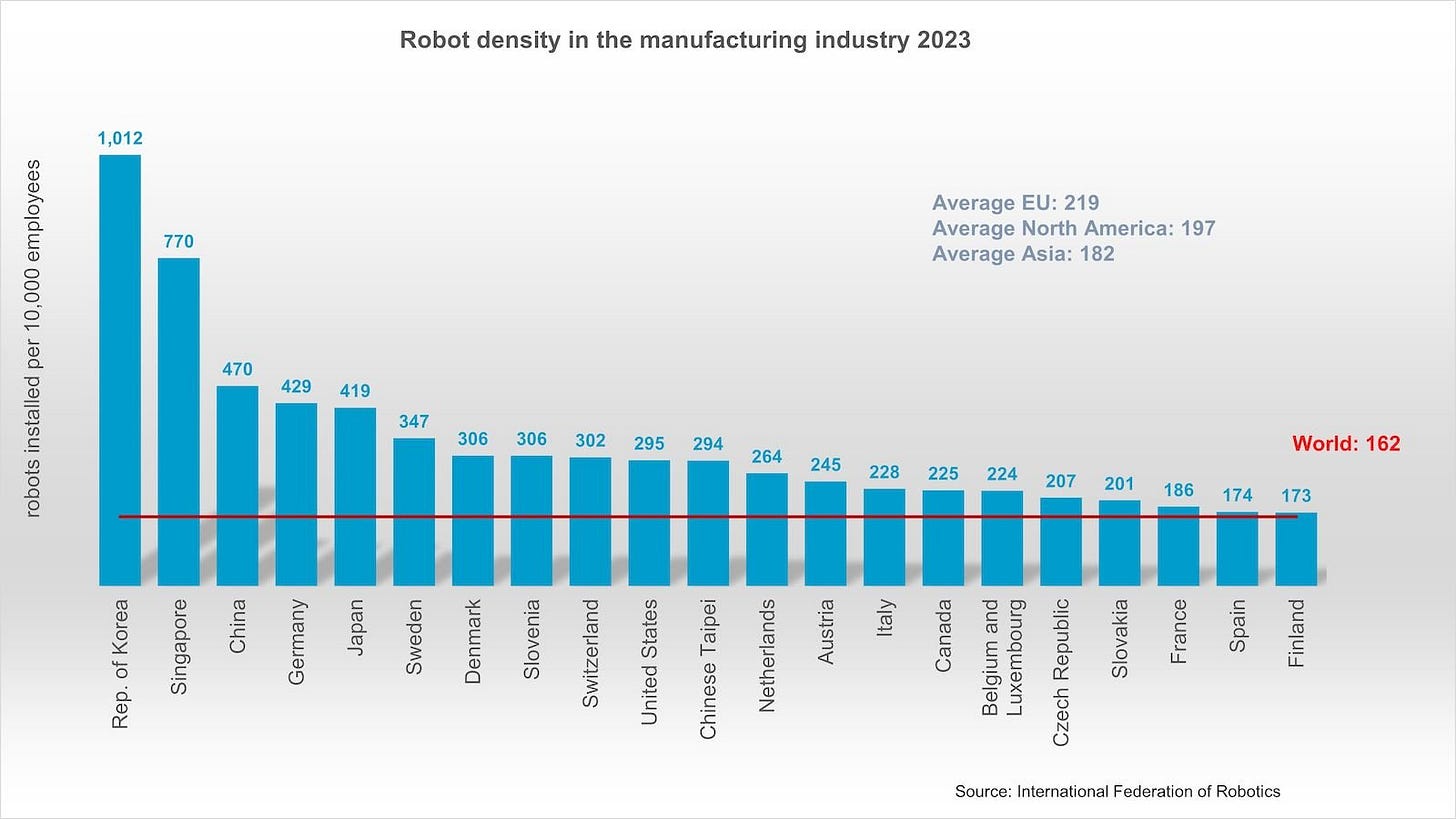

So America is significantly behind in absolute terms, but that’s not such a big deal because China has a lot more low end manual manufacturing, right? Surely what high end manufacturing industry we’ve retained in the US is more automated than China?

Well, that used to be true, but no longer. In 2017 China had 97 industrial robots per 10000 manufacturing workers compared to 200 in the US2. Fast forward to 2023 and China has ~5x’d it’s robot count per manufacturing worker while simultaneously growing its human manufacturing workforce. The robot growth factor over the same period for the (shrinking) human industrial workforce was <0.5 in the US.

The picture that this paints is one of increasing industrial sophistication in PRC and worsening industrial stagnation in the United States. This comports with vibes felt on the ground in both places, and with all manner of candid video evidence of Chinese factories that you can see on YouTube.

What’s worse is that these data come out with about a year of lag. It’s entirely possible that PRC catches up with South Korea in robots per capita by late next year if they keep this pace up, or, as I suspect they are doing, accelerate it.

What is to be done?

First, we must handle the problem of collective denial. Rah-rah patriotic flagwaving currently drowns out realistic assessments of America's economic and military position. We must realize that standing still while China to 5x's its industrial robot fleet is setting ourselves up for economic irrelevance twenty years from now. We must admit that we have no slack industrial capacity for weapons systems production, let alone civilian goods. The task of rebuilding our military industrial complex is isomorphic to the task of reshoring a large fraction of civilian industrial capacity. World War II-era propaganda about Liberty Ships and Flying Fortresses worked a little too well, and now Americans have a model of the world economy that is based in fantasy. This is incredibly dangerous self-delusion.

We must swallow a bitter pill that American manufacturers and policymakers have long avoided: the main reason people offshore to China nowadays is access to a dramatically more sophisticated manufacturing sector than anywhere else in the world. China wins this contest by default, Western economies must present a competitive alternative to Chinese industry, and to do that we must to make peace with the fact that it will be expensive and difficult.

We also cannot replace one fantasy with another. There is no AI-derived productivity silver bullet. While AI will be helpful for getting maximum utility out of our robot fleet, this is an issue of severe physical equipment shortfalls. We also can't let ourselves be distracted by flashy biomimcry demos, the kryptonite of the robotics field. Humanoids might be good at folding laundry or wiping butts in nursing homes some day, but they are no substitute for actual industrial automation here and now. We need to install an order of magnitude more robots, those robots must be actual useful industrial robots, and anything we do to improve dexterity or intelligence should be a secondary consideration to production volume.

Second, we must realize the urgency and stakes of this situation. If we do not turn it around - which will require whole of government effort and some very politically painful changes to the incentive structures around our system of finance - we are screwed. I don't mean abstractly screwed in the sense of losing a prestige contest like the 20th century Space Race with the Soviets. I mean materially screwed, like can't replace the power grid after a cyber attack screwed, can't build warships faster than PRC can sinks them screwed, vulnerable to total supply chain collapse screwed, no more globally competitive high margin physical products in any category screwed.

Third, we must take concrete action immediately. Things got this way in part due to large Western investments in Chinese industrial capacity. Western financiers much of the 1990s and 2000s going halfsies with PRC municipalities, provincial governments, and state-owned corporations on property, plant, and equipment spend for new ventures. This has slowed in recent years as geopolitical tensions have ratcheted up, but that's not enough. Policymakers must cut off this flow of capital entirely. These investment restrictions must be comprehensive, international, and punishing to those who refuse to comply. Zero dollars should flow from America or Europe to Chinese factory buildout programs. We must make Chinese manufacturing an uninvestable category for global finance.

There's also the issue of technology flows into PRC. In addition to restricting the flow of capital, the pipeline of robotics technology from Germany and other European countries must be shut off. This will do immense damage to the German economy, and they will have to be compensated in some way, so American policymakers should expect to pay up to get it done and done quickly. The sanctions and export restrictions regime developed to keep equipment out of Russian and Iranian hands should also be applied aggressively to this problem. There's precedent with semiconductor restrictions, so it will be mostly a matter of adding a lot more items to that list.

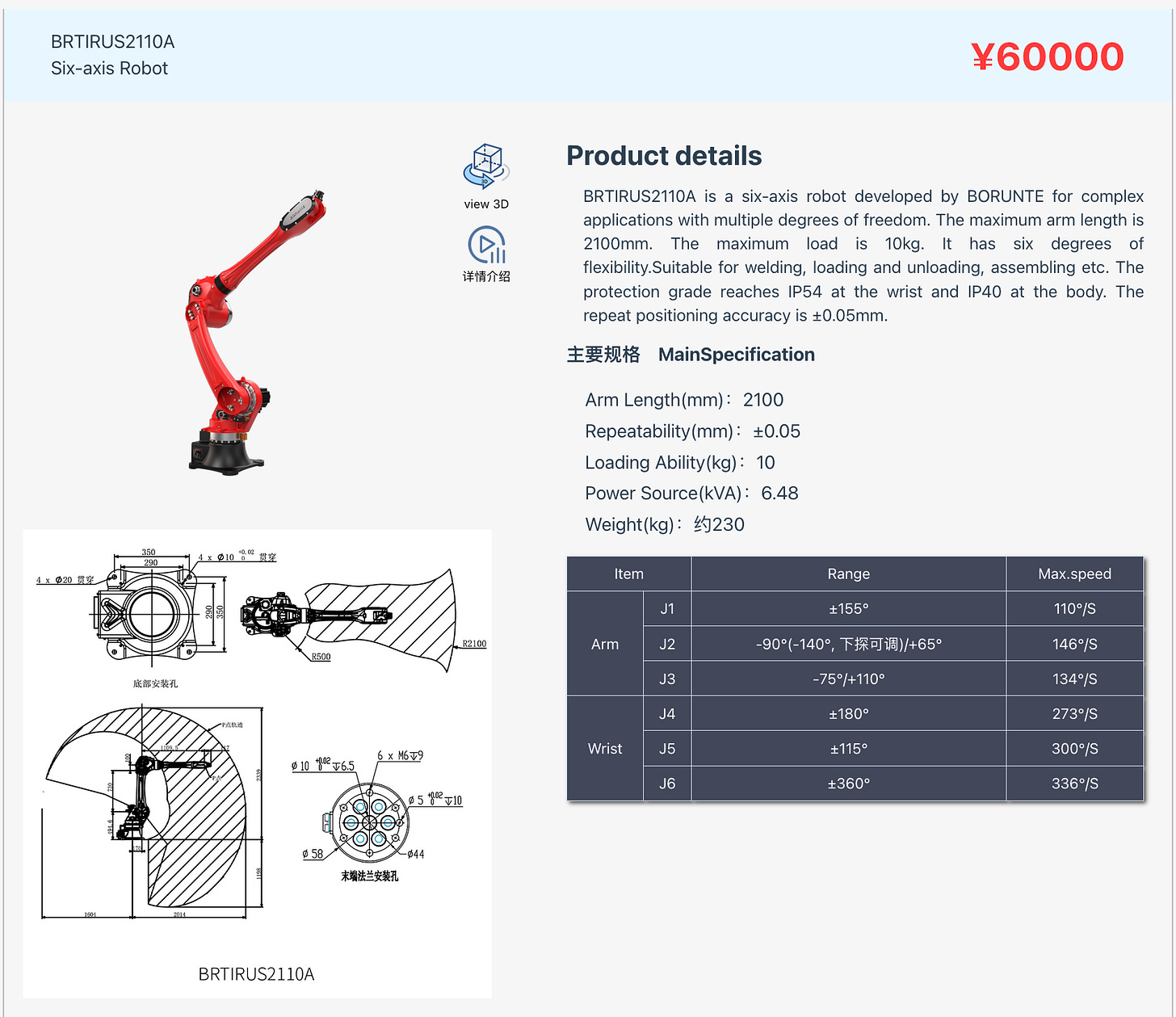

Finally, we need dollars to go into industrial automation at >10x current levels or we won't be able to maintain our economy in a trade dustup with PRC for that matter, let alone win a war. Legacy industrial automation providers are locked into cost models that guarantee uncompetitiveness. There is no American Borunte making <$10000 six-axis arms (yet). Direct subsidies should flow into robotics startups and into their potential customers, not into the same robotics companies that failed to keep up with Chinese advancements.

Since the most pressing need is in the defense sector, we ought to make automated production at scale a mandatory design requirement for future munitions purchases, and dole out the capital necessary to make it happen ahead of when it is needed. I expect Anduril et al to be much more able to keeping up with this sort of requirement than Lockheed or Boeing.

We can also turn the dial on tax treatment of industrial automation. The Advanced Manufacturing Tax Credit implemented by the CHIPS Act must be expanded in scope to cover as much industrial automation as politically feasible. Manufacturing equipment should be exempted from state sales tax wherever possible. This would require a sizable amount of legislation in a lot of different jurisdictions so it ought to be pursued separately from direct subsidies or improved procurement problems.

Das kapital (properly understood)

I’ll conclude with a more abstract point: a lot of the problems we have with our physical economy come from a postmodern understanding of “capital”.

To Karl Marx or Andrew Carnegie, capital was the literal means of production, i.e. tools, factories, and designs. Financial capital was an abstraction atop those assets. The word “capital” in common usage today most often refers to financial capital, money in a bank account. We refer to classical capital as “real capital” or, even more obnoxiously, “complex product systems”. Obviously accountants and economists have a more nuanced and way of talking about this, but when a firm raises capital it is almost always in the form of dollars. You see very few venture capitalists giving startups 5-axis mills or delta bots.

We need a functional, liquid financial capital system in order to develop and deploy real capital. But if that financial system fails to keep up with the productive capacity installation rate of its much less sophisticated cousin across the Pacific, it is not working. We must treat the financial system as a support function for technology development and deployment, not as the primary objective of industrial policy.

Errata and future topics

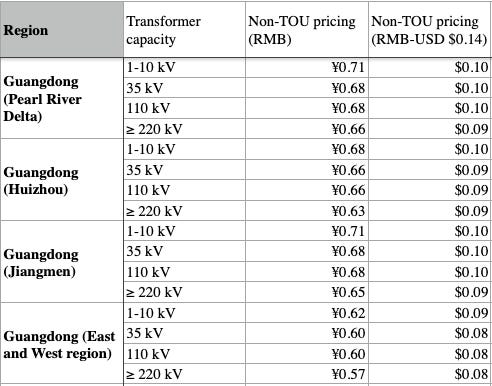

I recently wrote a piece on how America can generate cheaper electricity than China. If we solved that, everything I suggest in this piece would be much easier. If you found the above interesting you should check that out:

America can beat China on energy

America needs to start beating PRC on basic industrial stuff if we want to remain economically relevant in the 21st century. It will take some time to get better at things like phones and drones, but energy generation is a different story. I've been poking around a bit inside some electricity pricing datasets lately, and this has led me to the conclusio…

My next piece will probably be about the precision industrial and scientific automation as I recently attended the SPIE Photonics West trade show and came away with some thoughts on the subject.

At some point in the next few weeks I'm going to publish a design sketch of what vertically integrated domestic robotic arm production might look like. I hypothesize that we can make these things very cheaply and I am gathering resources to test that hypothesis at some point in the next year or two.

If any of that sounds interesting, please subscribe so you can get them in your inbox whenever they come out. If you're already subscribed, thank you for the vote of confidence! Please consider upgrading to a paid subscription if you'd like to support my blogging sidequest.

Disclosure:

I founded and run an industrial automation company, General Fabrication. Please ping me with manufacturing problems that we could solve with a domestically designed and built robot. We also sell a very capable industrial 3D printer, which you should buy if you work in the defense sector and don't want your network compromised by a Bambu. We would obviously benefit financially from the policies I lay out above, particularly if somebody in the new administration decided to deploy a couple trillion dollars into American robotics (jk, unless 👀). Depending on how you look at it that means that I have skin in the game or a significant bias, caveat lector.

Blitzkrieg but with robotics

I find this way of doing per capita stats to be really annoying but I’m just going to use what IFR uses for consistency’s sake

The first step in fixing a problem of this magnitude is recognizing the seriousness of the situation. Thank you for your contribution to that step. We are over invested in social media companies and mobile phone apps, and are about to exceed the marginal utility of another building full of GPU racks. It’s time for Silicon Valley to start investing in extruded aluminum and brushless motors.